Feed safety has always been a topic of great concern to the livestock and poultry feed industry.

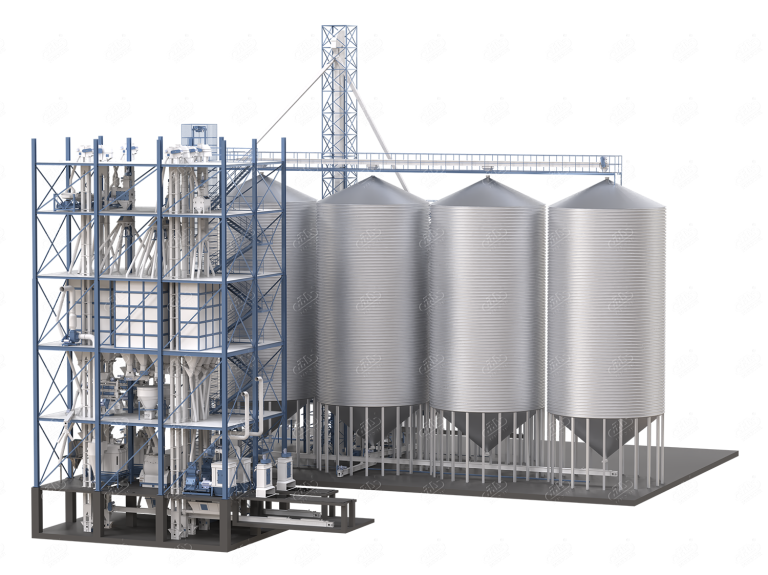

The livestock and poultry feed solutions and equipment provided by Hexie ensure the best and precise results of feed production.

Poultry feed comes in many forms, there are two main types of feed, pellet feed and powdered feed. Both products have similar production processes. After the powdered feed is completed, it can be made into feed pellets through pre-conditioning, granulation, cooling and screening.

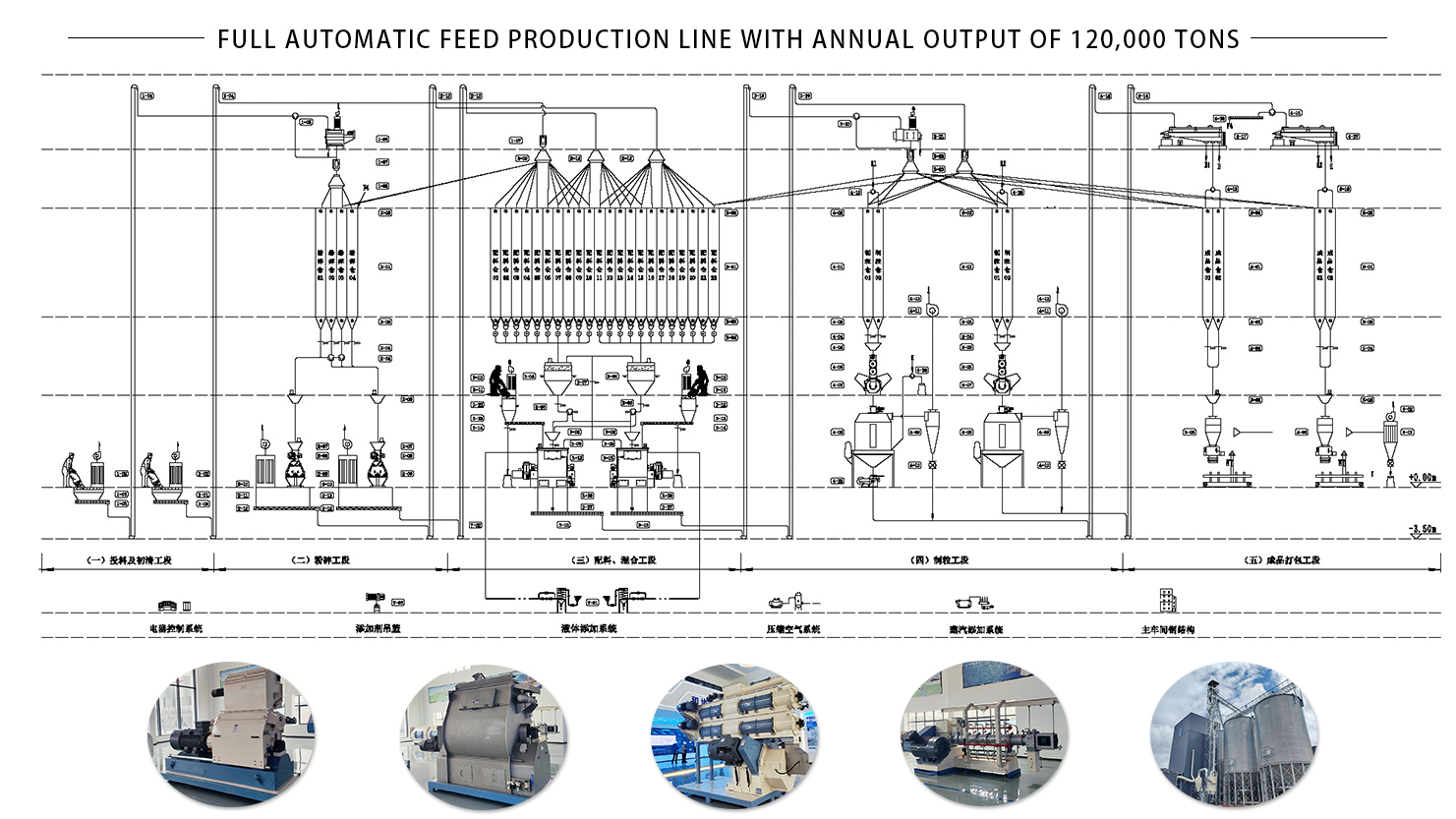

The complete pellet feed production line mainly includes these processes:

Raw Material → Grinding → Mixing → Pelletizing → Pellet Cooling → Pellet Crumbling → Screening → Packing

Powdered feed is a part of the complete feed production process. After the raw materials are finely crushed and mixed, it can prevent animals from being picky eaters and causing nutritional imbalance. The purpose of using powdered feed is to provide a balanced food supply for poultry, help poultry grow, and reduce death losses. In addition, feeding powdered feed is more efficient. When producing powdered feed, the raw materials are crushed, mixed and packaged.

Pellets are made from powdered products. The purpose of pelleting is to facilitate transportation and feeding. The nutritional value is the same in each pellet, so farmed animals consume all the good nutrients in the pellets.

The safety of feed has always been a topic of considerable concern for the livestock and poultry feed industry. The livestock and poultry feed solutions and equipment provided by Hexie ensure the best and accurate feed production results.

Range: 0.5-100t/h.

Hexie's design philosophy is to meet customer needs and provide customers with the highest quality solutions. We recognize that customers are still pursuing high-quality products that meet market competition under the pressure of rising raw material prices, energy consumption costs and labor costs. Hexie's design philosophy is to continuously improve and improve processes and equipment so that customers can obtain the best profits, which is the goal we have always pursued.

Poultry feed requires good pre-conditioning system

Poultry feed contains a lot of grains and is relatively high in fiber. A good pre-conditioning system is the key to success in making poultry pellet feed. Sufficient direct and indirect steam heat and moisture will soften the highly elastic fiber stock. Cooked starch is the perfect binder for forming granules.

The right amount of added fat

Adding too much fat to the recipe will produce a large amount of fine powder during the granulation process. It is recommended to add 1% fat to the mixer, which will reduce wear on the die holes and increase the output of the granulator. If the formula requires any additional fat, it can be sprayed directly on the feed pellets to increase the fat content and quality on the pellet surface.