Product Performance

Perfectly combined with the batching system, the operation is simple and convenient

Real-time reflection of all data batches, automatic/manual adjustment of accuracy

Multiple liquids can be added at the same time, easy to combine

Liquid preparation and spraying are fully automated without manual operation

Using advanced spraying technology, there is no agglomeration residue in the mixer

Efficient pipeline cleaning, anti-drip technology, uniform and no agglomeration

Perfect heating and heat preservation function, save worry and effort

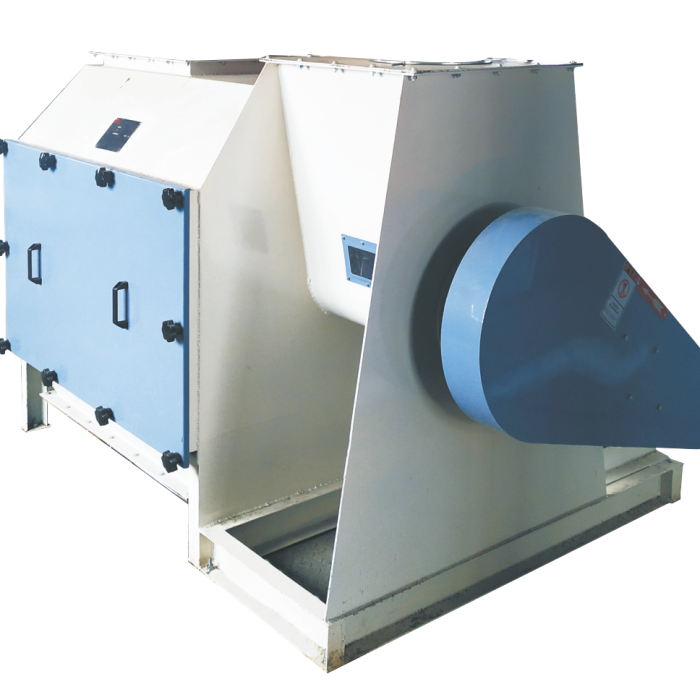

Roller Liquid Spray System

Combined operation of host computer/touch screen, data reports can be printed at any time

Use the world's top nozzles to ensure the spraying effect

High-precision sensors adapt to more complex environments

All data errors are reflected in real time, which can automatically improve the accuracy

The liquid feeding system is fully automated, without manual liquid addition;

The accessories are selected from the world's advanced brands, with low maintenance rate and high reliability

Self-cleaning spraying system to minimize agglomeration

The main engine adopts a special auger method to ensure that the grease is sprayed evenly

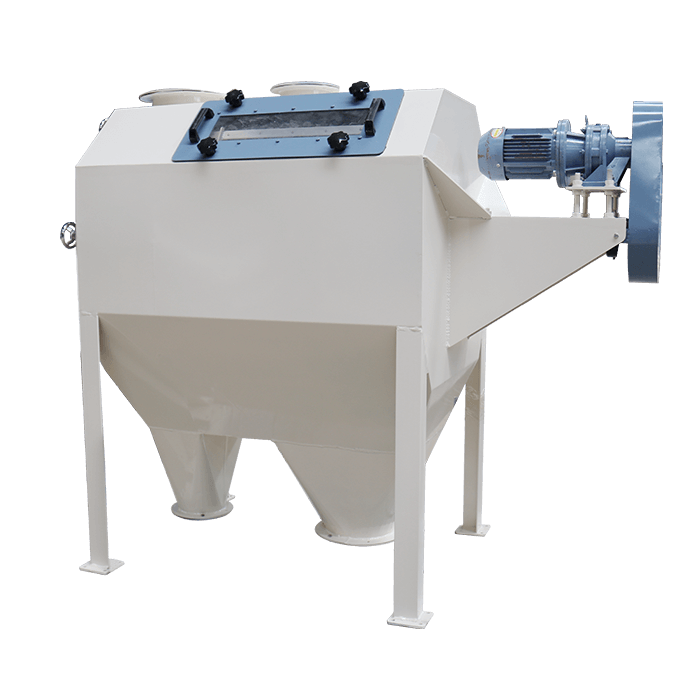

Easy to operate

- 1. Movable operation door, convenient maintenance.

- 2. Multi-stage linkage press screen mechanism makes it more convenient to change the screen.

- 3. Optimized pin shaft and pin sleeve structure, more convenient replacement of hammer.

- 4. A full range of linkage control system, always protect the safe operation of equipment.

- 5. Technical description, product model, main engine power, feeding power, rotor diameter, number of hammer,capacity.

Note: The above parameters are indicators of the following conditions: raw material is corn, moisture ≤13%. The volume weight is not less than 0.71t /m ³. The air suction rate per square meter screen piece is more than 55m³/min.

Specification

Batching accuracy: static accuracy errors 0.1%, dynamic accuracy error< 0.3%Automatic statistical batching report, raw material consumption report