Performance

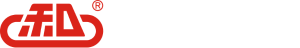

The structure is compact and the design is reasonable, which can significantly save floor space; the head wheel adopts a rubber coating process to increase the friction coefficient and improve transmission efficiency; the machine head increases the height of the discharge section, prolongs the material discharge time, and is equipped with a discharge port The adjusting plate and buffer device effectively reduce material return; the machine cover is lined with replaceable ultra-polymer wear-resistant materials; the cylinder adopts a bending and interlocking process, which has good strength and sealing performance; a balance tube is added to balance the space between the two cylinders of the machine body Pressure balance; large-opening maintenance operation door, convenient maintenance and replacement of the bucket; equipped with explosion vent, effective pressure relief and explosion explosion; suitable for continuous vertical lifting of powdery, granular, and small block materials.

- 1. The head wheel is covered with rubber technology, which increases the friction coefficient and improves the transmission efficiency

- 2. The tail wheel adopts anti-damage tail wheel, which will not damage the material

- 3. The machine head has its own explosion vent, which is highly safe

- 4. Optional non-return, speed measurement, anti-deviation device

- 5. Cycloid needle or hard tooth surface reducer can be selected according to customers’ need

- 6. It is widely used in the transportation of various granular and powdery raw materials in grain warehouses, docks, grain and oil processing plants, feed plants, pharmaceuticals, brewing and other industries

Specification

| Model | TDTG36/23 | TDTG36/28 | TDTG40/28 | TDTG50/28 | TDTG60/28 | TDTG60/33 |

| Capacity(CBM/H) | ~20 | ~35 | ~55 | ~80 | ~120 | ~180 |

| Power(KW) | 2.2-4 | 2.2-5.5 | 2.2-5.5 | 5.5-15 | 5.5-18.5 | 7.5-22 |

Conveying height(M) | H≦40 | |||||