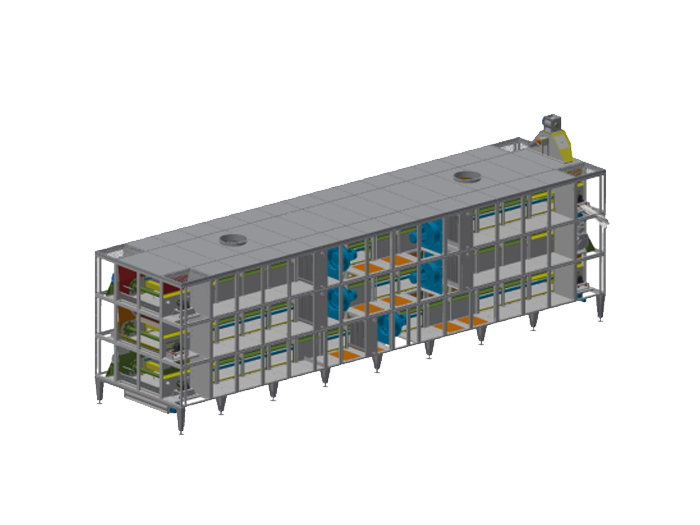

Performance

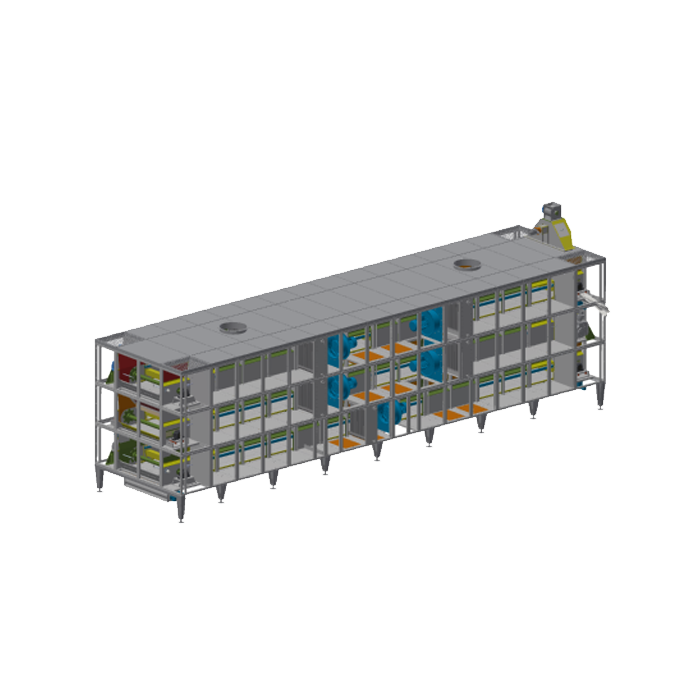

HXHZD series partition horizontal dryer is analyzed and compared by our technical staff on the drying equipment of many companies in the same industry from the aspects of production capacity, steam energy consumption, drying water uniformity, equipment operation stability etc, and on the premise of fully researching the actual production and operation of the equipment, the new generation of drying equipment is independently developed, which has the characteristics of compact structure, high thermal efficiency and uniform drying and dehydration.

Product Features

1. Servo pendulum distributor

The distributing device is controlled by Siemens controller and servo motor, which can freely set the width of the cloth and the speed of each point in the distributing process, effectively improve the uniformity of the material on the screen plate, avoid the short-circuit phenomenon in the air path, and affect the uniformity of drying water

2. Heat preservation treatment

The HXHZD type dryer is covered with 50mm insulation layer around the body, and the top is covered with 100mm insulation layer, which effectively reduces the heat loss. The body of the dryer is higher 5-10 degrees than the ambient temperature, and the energy saving is 10%-30% compared with the old dryer without good insulation layer.

3. Sieve plate

The sieve plate is made of stainless steel plate punching long round holes and coated with stainless steel wire mesh. This process can produce all particles above 1.0mm, and increase the opening rate of the original screen plate by nearly 30%. Moreover, the screen plate is sprayed with sintered Teflon anti-stick material, which has the characteristics of non-stick material, which can effectively reduce the number of cleaning screen plates, reduce labor force and improve production efficiency.

4. Sieve mesh

Adopt high temperature polyester mesh belt imported from Germany, the effective diameter can reach 0.4mm, suitable for small particle size of extruding feed, with high porosity, uniform air distribution characteristics.

5. Structure

Horizontal forward zoning reflects the working mechanism of high moisture and high temperature drying and low moisture segregation drying, which can achieve low discharge temperature and retain more nutrients in feed while saving energy.

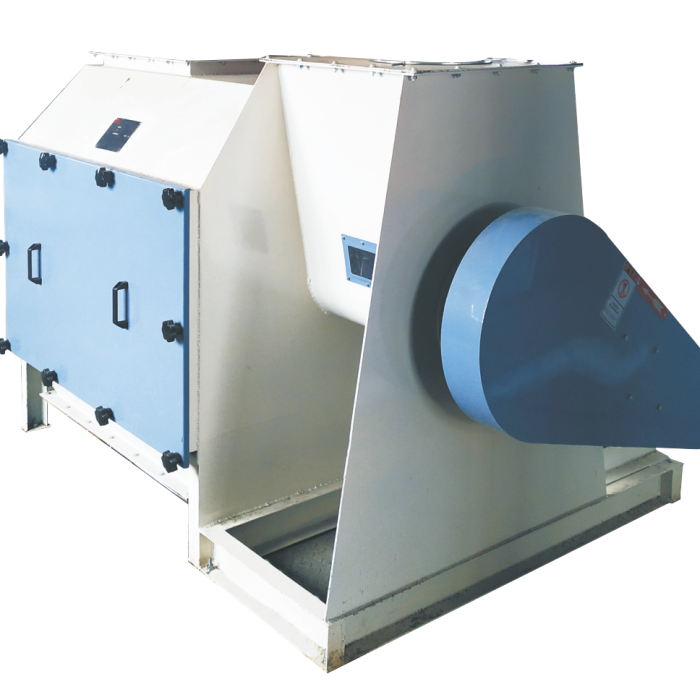

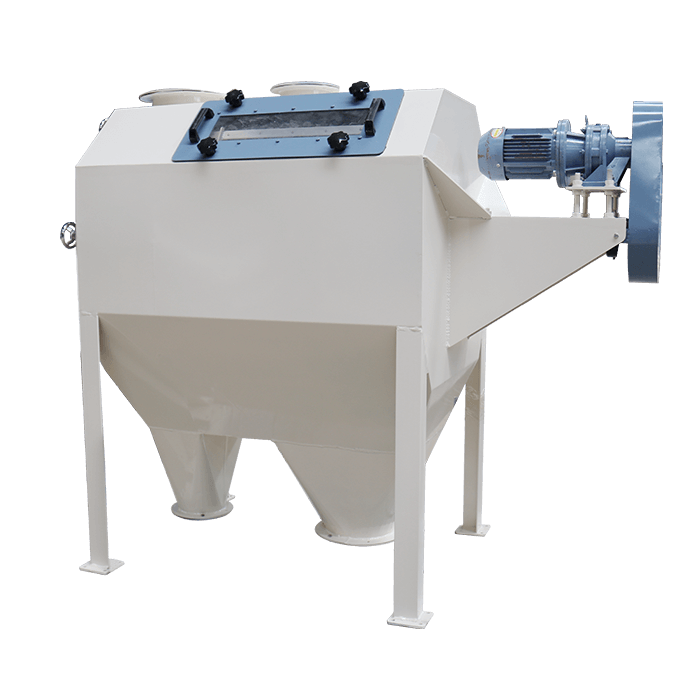

6. Wind path

The single wet discharge port is used to effectively control the moisture discharge. And the use of upper and lower, left and right circulation air path, effectively improve the uniformity of drying water, drying uniformity is not higher than ±0.75% water.

7. Control

Automatic control system (automatic moisture removal, automatic temperature control, automatic adjustment of the size of the butterfly valve, formula record management function and remote detection function), simple operation, stable control, weakening human factors

8. Heat source

Can choose to use a variety of heat sources, flexible and stable control oven temperature in 60~130℃ adjustable.

The distributing device is controlled by Siemens controller and servo motor, which can freely set the width of the cloth and the speed of each point in the distributing process, effectively improve the uniformity of the material on the screen plate, avoid the short-circuit phenomenon in the air path, and affect the uniformity of drying water.

Technical Description

| Model | Capacity of floating(t/h) | Capacity of sinking(t/h) |

| HXHZD4×10×2 | 3-5 | 2-3 |

| HXHZD4×12×2 | 5-6 | 2-4 |

| HXHZD4×14×2 | 6-8 | 3-5 |

| HXHZD4×16×2 | 7-9 | 4-6 |

| HXHZD4×18×2 | 8-10 | 5-7 |

| HXHZD4.5×22×2 | 13-15 | 10-12 |

| HXHZD5×12×2 | 8-10 | 5-7 |

| HXHZD5×14×2 | 9-11 | 6-8 |

| HXHZD5×16×2 | 10-12 | 7-9 |

| HXHZD5×16×3 | 15-16 | 11-13 |